Airteq Introduces Dust Monitoring by Direct Sensing

BAT (best available techniques).

In the UK policies and practices are being implemented to prevent and control industrial emissions in order to ensure a high level of environmental and human health protection. Many of these policies incorporate the concept of the BAT (best available techniques). The BAT concept has evolved as one of the key elements for setting Emission limit values and other permit conditions in preventing and controlling industrial emissions.

In the UK policies and practices are being implemented to prevent and control industrial emissions in order to ensure a high level of environmental and human health protection. Many of these policies incorporate the concept of the BAT (best available techniques). The BAT concept has evolved as one of the key elements for setting Emission limit values and other permit conditions in preventing and controlling industrial emissions.

In ‘Best available techniques’ means the most effective and advanced stage in the development of activities and their methods of operation, which indicates the practical suitability of particular techniques for providing the basis for emission limit values and other permit conditions designed to prevent and reduce both emissions and the impact on the environment as a whole.

More frequent Dust measurements on dust filters would be required to determine the effectiveness of a filter to lower any dust concentrations being returned into the workplace. Monitoring of this by normal gravimetric methods would take time and additional resources to gain any meaning full results.

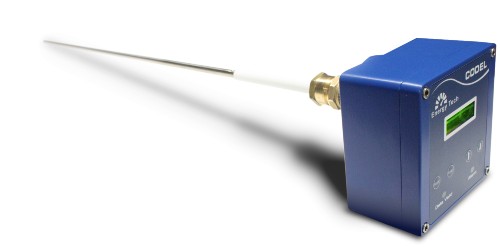

Our energy tech 301 dust monitor provides direct sensing methods for actual particulate concentration, with a real-time visual of mg/m3 carryover. The equipment is capable of detecting dust concentrations of less than 1mg/m3 in small ducts and can measure particles as small as 0.1micron.

Features Include:

- Can be used in duct sizes from 250mm to 5m

- Direct sensing method; actual particulate concentration

- Automated online zero and span checking facility

- Minimal maintenance requirements

- Multi-functional remote connectivity for site wide monitoring of emissions.

- Both Analogue and RS485 output for constant and recorded measured values

- Option for audible and visual alarm for early warning of exceeded levels